Oktoberfest

From the looks of the bottle labels removed, it appears that my favorite beer over the past few years has been a nice Oktoberfest. Found a nice Marzen Oktoberfest in Green Bay a few weeks ago.

We brewed it today and everything went very well. Hope it turns out. Stay tuned.

Learn from mistakes

Our first batch in the new fermenter did not turn out very well. No fermentation. The sample bottles had a little fizz when uncapped. They had a nice color, but no alcohol. Smooth start, tasteless middle and no ending taste. 😛

We tried to recreate our steps to determine what went wrong. We narrowed down to how we applied the yeast. We believe the yeast starved.

So, we dumped it out. A sad moment.

American Amber – Second Try

After enjoying perhaps our finest brew last year, we tried another batch of American Amber in the new FastFerment brewing system. Tried using honey with the yeast instead of priming sugar. We will see how it turns out.

After two weeks, just changed the lower ball to remove the heavy sludge at the bottom to start the second fermentation process. Pretty slick and easy process.

Not a lot of fermentation action, worried that the beer might be flat. We will see in a couple weeks.

New brewing system

Installed FastFerment, a new brewing system. The advantage is that you don’t have to transfer into a secondary fermenting carboy. Just change the lower ball after 2 weeks. Sounds pretty slick!

Check out the video at

https://www.thefastrack.ca/main/fastferment

We mounted the system to the stud walls. Fits nice between the sink and the stove.

Dortmunder First Lager

Trying out first lager a Dortmunder Export. This German Lager did not have the requirement to ferment at 40 degrees. The basement in the winter is a pretty constant 60 degrees, which should work. Ground the two types of grain, the first was ground too fine, almost like flour. Made some adjustments to just crack the next bag of grain. The color was a nice pilsner shade while steeping. Boiled the wort in the smaller pot and John caught it just before another boil over. Added the two types of hops at three different times. The wort chiller on the inside and 30 lbs of ice cooled the wort down quickly. Poured the wort through a filtered funnel. Made lots of foam in the carboy, perhaps too much. Cooling 3 gallons of boiled, sterile water while we had dinner. Added the water to bring to about 5 gallons. Setup the big tube to allow the air bubbles to escape into a pan of water. A little clean up and we are done. A good brew day!

Bottle Label Removal

One of my least favorite parts of brewing is removing the labels from commercial beer bottles. Experienced home brewers like Mineral Springs Brewing understand the problem and win my top honors for being the most easy to remove (and most entertaining) bottle labels. Followed by Fat Tire Amber, my lucky beer (see Hole in One story), is easy to remove labels in one piece, with just some glue to easily remove. Rusty Red from O’so Brewing has just two glue lines, but are tough. Perhaps my favorite new beer (other than MSB Beer Wisperer Lager) of the year was the Staghorn Octoberfest from New Glarus Brewing Company, but the bottle labels are a real pain to remove.

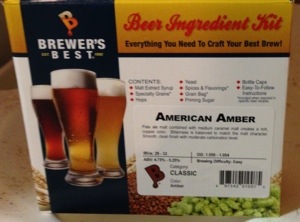

American Amber

While in Green Bay WI, we found a nice store called House of Home Brew http://www.houseofhomebrew.com/ where we found a nice American Amber kit.

We also picked up a wort chiller and a new bottling tube.

On a bight sunny, but cold and windy January day, we started brewing our third batch.

The instructions were good, with helpful tips – although more useful if you read before just diving in 🙂

Started boiling 2.5 gallons to steep the grain bag, but realized the tip to use more water if you have the equipments, we we can, so we added more water. Getting this much water to a rolling boil took a little longer. Nice tip to warm the liquid malt extract (LME) container in hot water to make it pour easier. Added the dry malt extract (DME) and the first batch of hops. Had a small boil over, but caught it quickly.

While watching the boil, we enjoyed a few home brews from brother Tim Pelton’s Mineral Springs Brewing http://mineralspringsbrewing.com/ and preferred Rod Carew Irish Red over the still very drinkable Scottish 80 shilling with the Chuck Taylor Converse All Star logo. Also enjoyed cousin Jeff Westra’s #2 and #5.

Transferred the wort into a smaller pot to cool with the new wort chiller with cold well water and stirred water, snow and ice around the outside of the smaller pot in the big pot. Everything worked really slick! Saved an hour as compared to other methods.

Transferred the wort into the 6.5 carboy through a filtered funnel to remove the chunky stuff.

Cleaned up the boil over mess and we were done for the day.